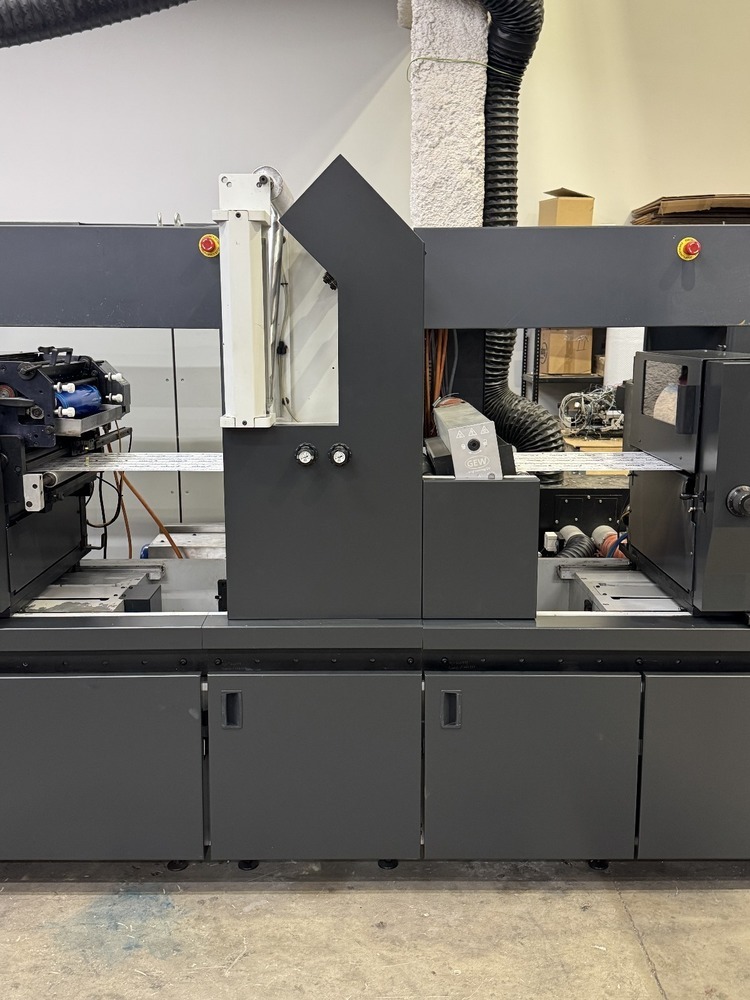

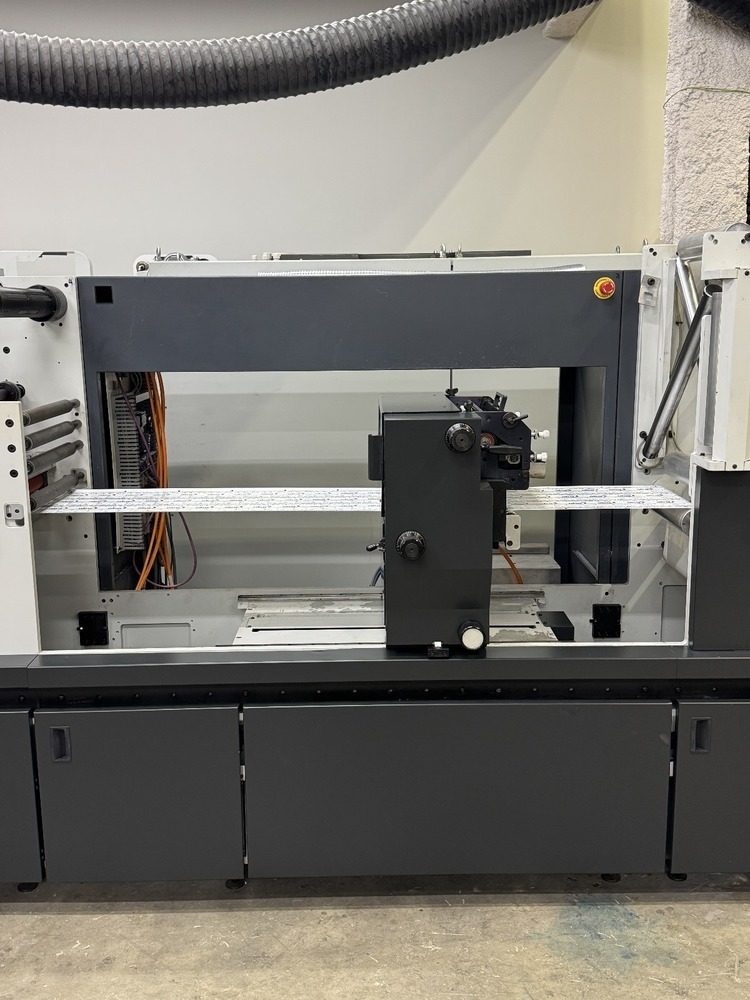

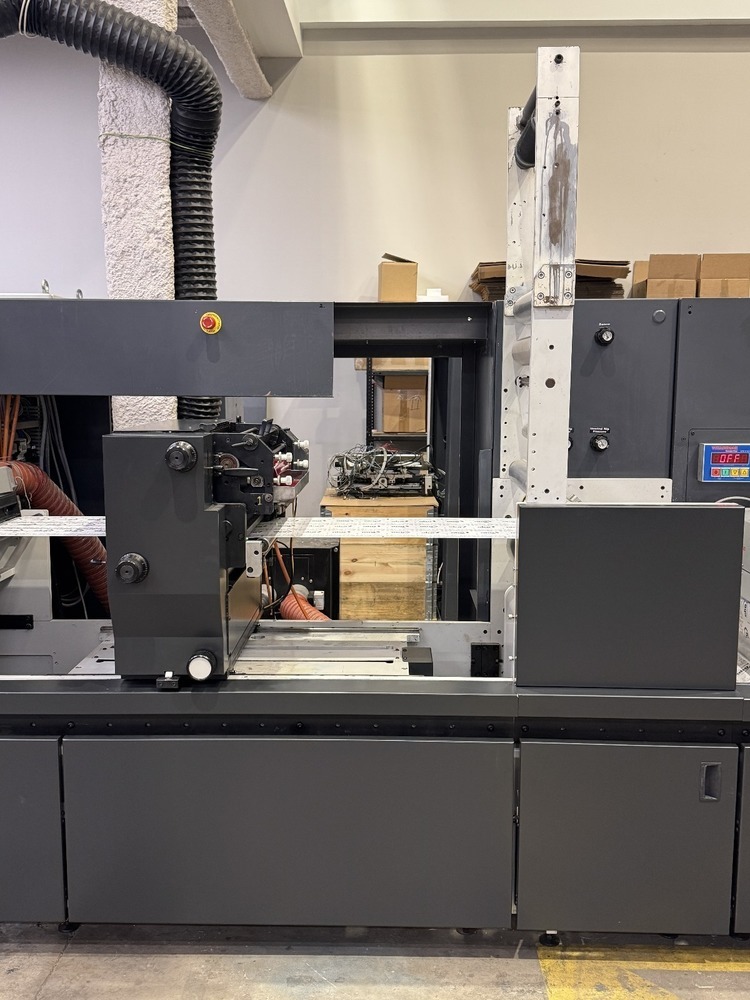

| Description: |

Complete overhauled<>Machine built to work right to left<>Unwind - 700 mm unwind, electronic web guide (edge guide sensor), splice table and web clamps, auto brake tension control.<>Corona treatment Vetaphone<>Infeed nip drive section, infeed dancer.<>Delam/relam module for printing on adhesive in either full or semi-rotary section with Air<>assist turn bar<>1st Semi rotary flexographic printing station with quick change cassette comprising<>stainless steel ink pan, pick-up roller, ceramic anilox roller, and reverse angle doctor blade.<>The station has auto pre-positioning and servo drive re-register<>GEW air-cooled UV curing unit 140w/cm<>2nd Semi rotary flexographic printing station with quick change cassette comprising<>stainless steel ink pan, pick-up roller, ceramic anilox roller, and reverse angle doctor blade.<>The station has auto pre-positioning and servo drive re-register<>GEW air-cooled UV curing unit 140w/cm<>Over laminating station suitable for super varnish, cold foil, self-wound and lamination<>with carrier with soft laminating option<>Mid-press dancer to allow full rotary coating<>Semi rotary die cutting station with 25,5” magnetic cylinder (24” maximum repeat).<>Outfeed nip drive section, outfeed dancer.<>Waste matrix stripping (maximum diameter 600mm)<>Rewind<>Scissor slitting, including 5 knives and removable knife shafts<>Back Scorer used for edge trimming the silicon carrier<>Single spindle rewind with variable tension control, 76mm air expanding shaft<>label length counter with batch and pause facility<>Second rewind shaft with 76mm shaft<>Maximum web width: 330 mm<>Minimum web width: 180mm<>Maximum repeat length: 24” (609,6 mm)<>Minimum repeat length: 2” (50,8 mm)<>Rewind maximum diameter: 500 mm |